Yes, carbon steel is magnetic because it contains iron, a metal known for its strong magnetic properties. That’s why you’ll often find carbon steel in motors, transformers, and magnetic tools.

But not all steel behaves the same. If you’ve ever been confused about why some steel sticks to a magnet and some doesn’t, you’re not alone. This article will clear that up for you.

We’ll explain the science behind carbon steel’s magnetism, the key factors that affect it, and situations where it might lose its magnetic pull.

You’ll also see how it’s used in real-life projects, how it compares to other metals, and how to pick the right steel grade for your job.

Understanding Carbon Steel Composition

Carbon steel is an iron-carbon alloy with 0.05% to 2.1% carbon by weight. Its magnetic behavior is primarily due to iron, which is ferromagnetic, meaning its atomic structure allows magnetic domains to align. While carbon itself isn’t magnetic, small amounts don’t interfere much with iron’s magnetism.

Unlike stainless steel, carbon steel lacks elements like nickel or chromium, which can reduce magnetic strength. This makes carbon steel generally more magnetic than many alloy steels.

However, as carbon content increases or additional alloying elements are introduced, magnetic strength may slightly decrease. Overall, the composition of carbon steel greatly influences how magnetic it is.

Why Carbon Steel is Magnetic: The Scientific Explanation

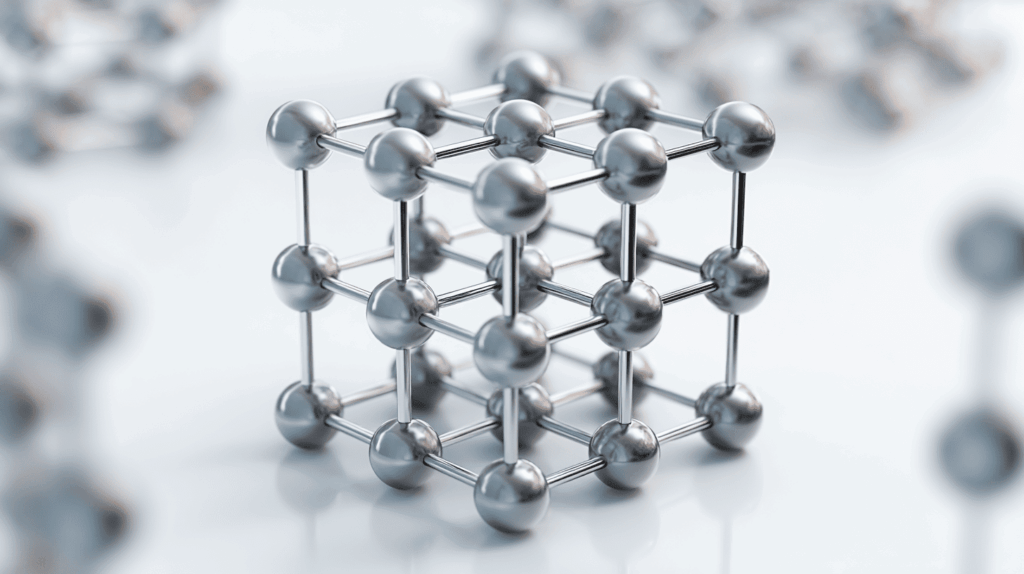

Carbon steel is magnetic primarily because it contains a high percentage of iron. Iron has a special crystal shape called BCC (body-centered cubic) at room temperature. This shape allows tiny particles called electrons to line up in the same direction, creating small magnetic fields.

When many of these zones point the same way, they form magnetic areas called domains. That’s what gives carbon steel its strong pull to magnets, especially when it’s in the ferrite phase (a stable, magnetic form of steel).

Carbon doesn’t create magnetism, but it does change the steel’s structure. Low-carbon steel stays mostly ferrite, so it’s very magnetic. High-carbon steel has more cementite and pearlite, which weakens its magnetism slightly, but it still adheres to a magnet.

What Affects Carbon Steel’s Magnetic Strength?

Several factors influence how strongly carbon steel responds to a magnetic field, including its composition and the processing method.

Carbon Content Impact

- Low carbon steel (0.05%–0.3%): High magnetic permeability; commonly used in transformers and automotive parts.

- Medium carbon steel (0.3%–0.6%): Slightly reduced magnetism; more rigid structure.

- High carbon steel (0.6%–1.0%+): Lower magnetic responsiveness due to more cementite (Fe3C) formation.

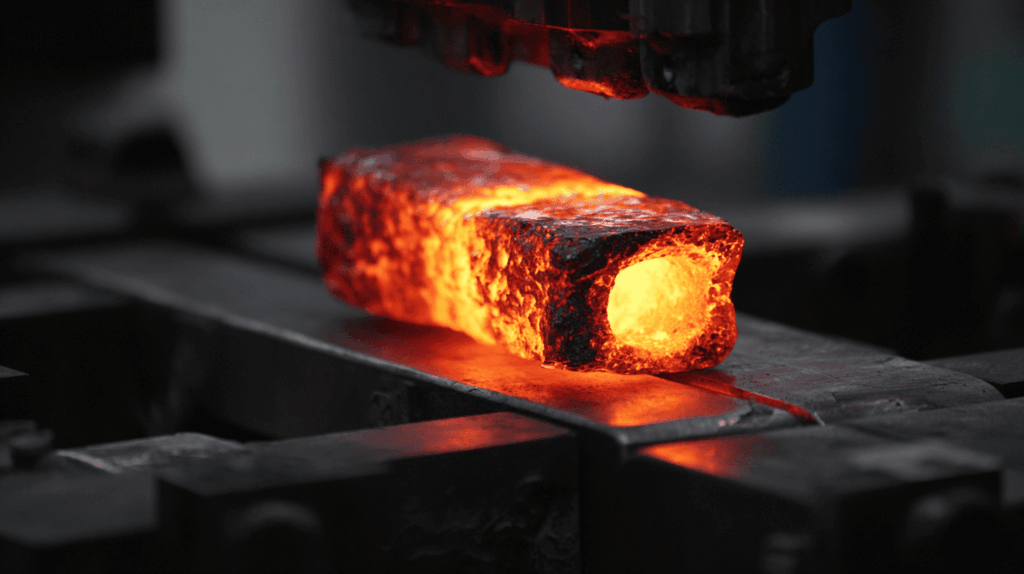

Heat Treatment Effects

- Annealing (slow cooling): Restores or enhances magnetic properties by reducing internal stress.

- Quenching/Tempering: This process alters the grain structure and can reduce magnetic strength.

- Curie Temperature: Around 768°C (1414°F); above this point, steel loses its magnetism.

Microstructure and Grain Size

- Smaller grain size = stronger magnetic properties.

- Ferritic microstructure (soft and ductile) = better magnetic alignment.

- Pearlitic microstructure (harder) = slightly weaker magnetism.

Alloying Elements

- Silicon: Enhances magnetic permeability.

- Nickel and Chromium: Tend to reduce magnetic strength.

- Manganese: Minor influence, but can reduce magnetic alignment in high concentrations.

By understanding these influences, you can better select or modify carbon steel for applications where magnetic performance is crucial.

Exceptions: When Carbon Steel Becomes Non-Magnetic

While carbon steel is generally magnetic, there are notable exceptions. One key factor is temperature.

When carbon steel is heated above its Curie temperature (around 768°C), its internal structure changes from ferritic (BCC) to austenitic (FCC).

Since the FCC structure doesn’t support magnetic domain alignment, the steel temporarily loses its magnetism. Once it cools back below the Curie point, it returns to its magnetic state.

Heavy alloying also plays a role. Steels with high amounts of nickel or chromium can adopt an austenitic structure at room temperature, rendering them non-magnetic or only weakly magnetic.

Additionally, in heat-treated steels, magnetism can vary across different zones depending on cooling rates and resulting microstructures.

How to Test and Select Magnetic Carbon Steel Grades

Wondering if your carbon steel is magnetic? You don’t need a lab; there are simple and advanced ways to find out.

- Basic Magnet Test: Hold a strong magnet close to the steel. A firm pull indicates magnetic behavior.

- Visual Indicators: Low carbon steels often look dull gray and are magnetic; austenitic types may be shinier and non-magnetic.

- Advanced Testing: Use Gaussmeters or magnetic permeability testers for precise results.

If you’re checking scrap material or verifying a component’s properties, these tests help confirm the magnetic nature of your carbon steel quickly and accurately.

Safety Tip: Always wear gloves when testing raw or sharp-edged materials.

Want to know how magnetic your carbon steel is? You don’t need special tools; just understanding the grade can tell you a lot.

- 1008, 1010, 1018 (Low Carbon): Excellent magnetic performance, easy to work with.

- 1045, 1060 (Medium Carbon): Good balance of strength and magnetism.

- 1080, 1095 (High Carbon): Stronger but slightly reduced magnetic response.

If you’re sorting scrap or checking material for a magnetic use, knowing the grade makes fast identification possible, even before running a magnet test.

Tips: Choose based on application: e.g., transformers need low carbon, cutting tools need higher strength. Consider corrosion resistance if used in damp environments.S

Where Carbon Steel’s Magnetism Matters Most

Carbon steel’s magnetic properties aren’t just scientific trivia; they’re essential to how it functions in real-world industries, from power generation to precision tools.

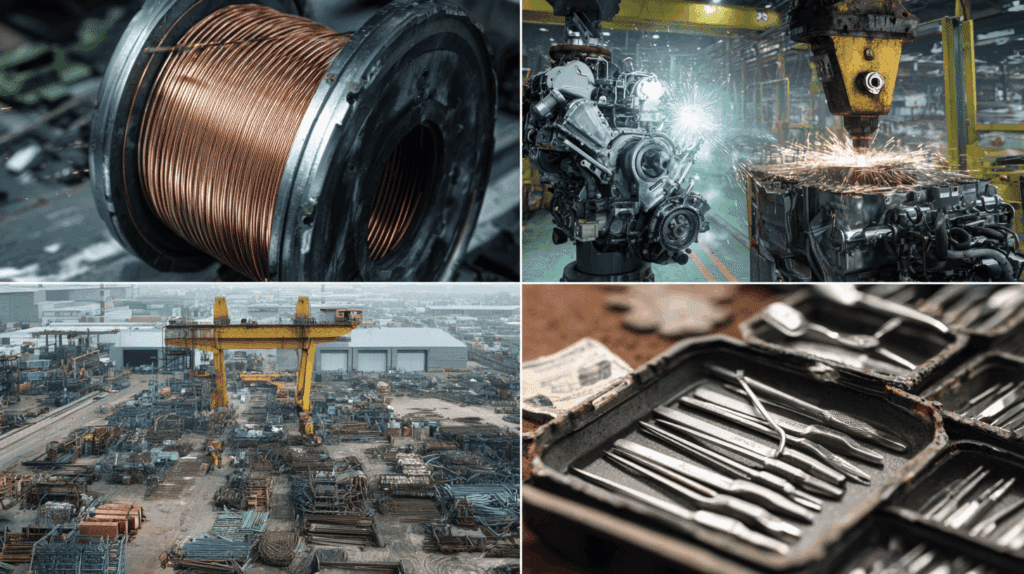

1. Electrical and Electronics

Carbon steel is widely used in:

- Transformer cores

- Generator components

- Electromagnets

Its strong magnetic permeability makes it ideal for conducting and shaping magnetic fields efficiently in these applications.

2. Automotive and Machinery

In the automotive industry, magnetic carbon steel is used in:

- Engine blocks

- Crankshaft components

- Magnetic fasteners

- Die-making tools

These components benefit from their strength, durability, and responsiveness to magnetic forces.

3. Construction and Infrastructure

In construction and heavy industry, magnetic carbon steel is used in:

- Magnetic lifting systems

- Railway braking technologies

- Conveyor belt separators

These applications rely on the steel’s magnetic response to move, control, and separate heavy materials efficiently.

4. Medical and Precision Applications

In the medical and precision fields, certain carbon steel grades are used in:

- Surgical tools

- MRI-safe instruments

- Magnetic targeting components

These tools benefit from controlled magnetism, allowing for precision, stability, and compatibility with imaging or light environments.

How Carbon Steel Compares to Other Magnetic Metals

Carbon steel is known for its strong magnetic properties, but how does it stack up against other common magnetic metals like stainless steel, cast iron, and electrical steel?

| Material Comparison | Magnetic Behavior | Use Case / Notes |

|---|---|---|

| Carbon Steel vs. Ferritic Stainless Steel | Both are magnetic, but carbon steel is generally stronger magnetically. | Ferritic stainless is corrosion-resistant; carbon steel is stronger and more versatile. |

| Carbon Steel vs. Austenitic Stainless Steel | Austenitic stainless steel is generally non-magnetic. | Carbon steel is preferred where magnetic properties are essential. |

| Carbon Steel vs. Cast Iron | Both are magnetic. | Cast iron is brittle and static; carbon steel is ductile and better for moving parts. |

| Carbon Steel vs. Electrical Steel | Electrical steel is highly magnetic due to its silicon content. | Electrical steel is ideal for transformers; carbon steel is cost-effective and versatile. |

Understanding these differences can help you select the most suitable material for applications where magnetism, durability, or cost are key considerations.

Myths and Facts About Carbon Steel’s Magnetic Properties

Myth: All steel is magnetic.

Fact: Austenitic stainless steels are not magnetic.

Myth: Galvanized steel isn’t magnetic.

Fact: Zinc coating doesn’t affect the steel’s magnetism.

Myth: Heat treatment destroys magnetism.

Fact: It can reduce but not eliminate magnetism.

Myth: Stronger steel means stronger magnetism.

Fact: Strength and magnetism are not directly related.

Myth: Only pure iron is magnetic; carbon steel loses magnetism.

Fact: Carbon steel remains magnetic because of its iron content.

Myth: Carbon steel is always magnetic under all conditions.

Fact: It loses magnetism above its Curie temperature but regains it on cooling.

Myth: Magnetism depends only on composition.

Fact: Heat treatment and processing also affect magnetism.

Myth: Only ferromagnetic metals respond to magnets.

Fact: Metals can be paramagnetic or diamagnetic, too, with weaker effects.

Wrapping it Up

Carbon steel sticks to magnets because it’s made mostly of iron. However, the strength of that magnetism can change. It depends on factors such as the amount of carbon in the steel, how it was heated or treated, and whether any other metals were added.

Low-carbon steel is usually the most magnetic. Higher-carbon or alloyed types may not respond as well. That’s why it’s smart to test your material, especially if you’re working on motors, sensors, or other precise tools.

If magnetism is important for your project, double-check the steel’s grade. It can make a big difference in how well things work.